Menu

Latest News

Products

1、 Product details:

10 ton mixed bed is the abbreviation for mixed ion exchange column, which is a device designed for ion exchange technology. The so-called mixed bed refers to the mixing and filling of a certain proportion of cation and anion exchange resins in the same exchange device to exchange and remove ions from the fluid. Due to the higher specific gravity of the cation resin compared to the anion resin, the anion resin is on top and the cation resin is on the bottom in the mixed bed. The general ratio of resin filling for yang and yin is 1:2, and there are also filling ratios of 1:1.5, which can be selected according to different resins. Mixed beds are also divided into in vivo synchronous regeneration mixed beds and in vitro regeneration mixed beds. The synchronous regeneration mixed bed operates and the entire regeneration process is carried out inside the mixed bed. During regeneration, the resin does not move out of the equipment, and the cation and anion resins are regenerated simultaneously. Therefore, fewer auxiliary equipment are required and the operation is simple.

The equipment for mixed bed treatment process includes mixed ion exchangers and in vitro regeneration equipment. The in vitro regeneration equipment mainly includes resin separators, anion (cation) resin regenerators, resin storage towers, hybrid resin towers, and acid-base regeneration equipment. The main characteristics of domestic mixed bed treatment technology are reflected in the resin separation and regeneration process. There are three types of resin separation and regeneration processes.

2、 Technical parameters:

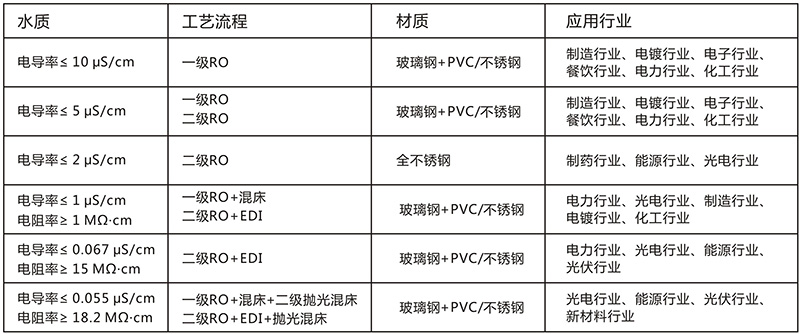

3、 Scope of adaptation:

Manufacturing industry: automotive glass, steel, paper, textile, etc

Power industry: boiler, thermal power generation, cooling cycle, etc

Electroplating industry: coating, lighting, cooling, metal plating, LED lights, etc

Optoelectronic industry: photovoltaic photovoltaic lighting, new energy LED lights, etc

Electronics industry: electrical chips, circuit boards, microcontrollers, electronic components, etc

Energy industry: oxide semiconductor silicon materials, polycrystalline silicon metal extraction, etc

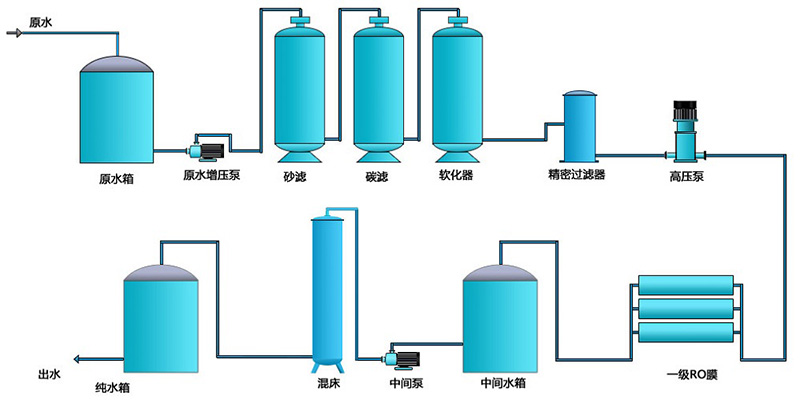

4、 Process flowchart:

Previous: No More

Next: No More