Menu

Latest News

Products

1、 Overview of Coating Wastewater Treatment Equipment:

The equipment uses ferrous sulfate to reduce hexavalent chromium in wastewater, and neutralizes it with lime to form insoluble chromium hydroxide. Reduce hexavalent chromium to trivalent chromium using ferrous sulfate under acidic conditions. Then, under appropriate temperature and alkaline conditions, iron oxide and chromium oxide precipitate together, and the remaining waste residue is separated using a filter press. To achieve the goal of wastewater treatment.

2、 Process flow of painting wastewater treatment equipment

Wastewater enters the pre mixing tank from the workshop, where ferrous sulfate is added. Fe2+reduces Cr6+to form Cr3+. After a chemical reaction, limestone is added to the wastewater to form Cr (OH) 3, Fe (OH) 3, and Pb (OH) 2 precipitates. Fe (OH) 3 forms colloids, adsorbs cations in the water, forms precipitates, and then passes through the sedimentation tank to meet the discharge standards.

3、 The generation of painting wastewater:

The coating industry, also known as the paint industry, is an industry that produces coating materials. It belongs to the fine chemical industry and is widely used in industries such as machinery manufacturing, transportation, light industry, and chemical industry. It can play a role in protection, decoration, or other functional applications. Nowadays, synthetic resin coatings made from petrochemical products have replaced oil-based coatings and natural resin coatings. Paint wastewater mainly comes from the production process and the cleaning process of ingredient tanks. The production process uses various chemical raw materials such as organic solvents and additives, and also contains a large amount of various high molecular weight organic compounds as thickeners and dispersants. Therefore, paint wastewater is generated. It is necessary to treat this type of water containing pollutants reasonably to ensure that it meets the discharge standards.

4、 The treatment method of painting wastewater treatment equipment:

1. Physicochemical method: As a pretreatment method for coating wastewater, it can effectively remove suspended solids, pigments, solid substances, heavy metals, and other substances from the water.

2. Air flotation method: using an air flotation machine to generate tiny bubbles in the water and stick them to pollutant particles, which then float to the surface to separate the pollutants. This method can be used for primary treatment after homogenization.

3. Coagulation method

It is a method of aggregating colloidal particles and small suspended solids in water by adding chemical agents to separate, coagulate, and flocculate them, collectively known as coagulation. When used in coating wastewater, it mainly removes fine suspended solids and colloidal particles from the water, reducing the turbidity and pigments of the wastewater.

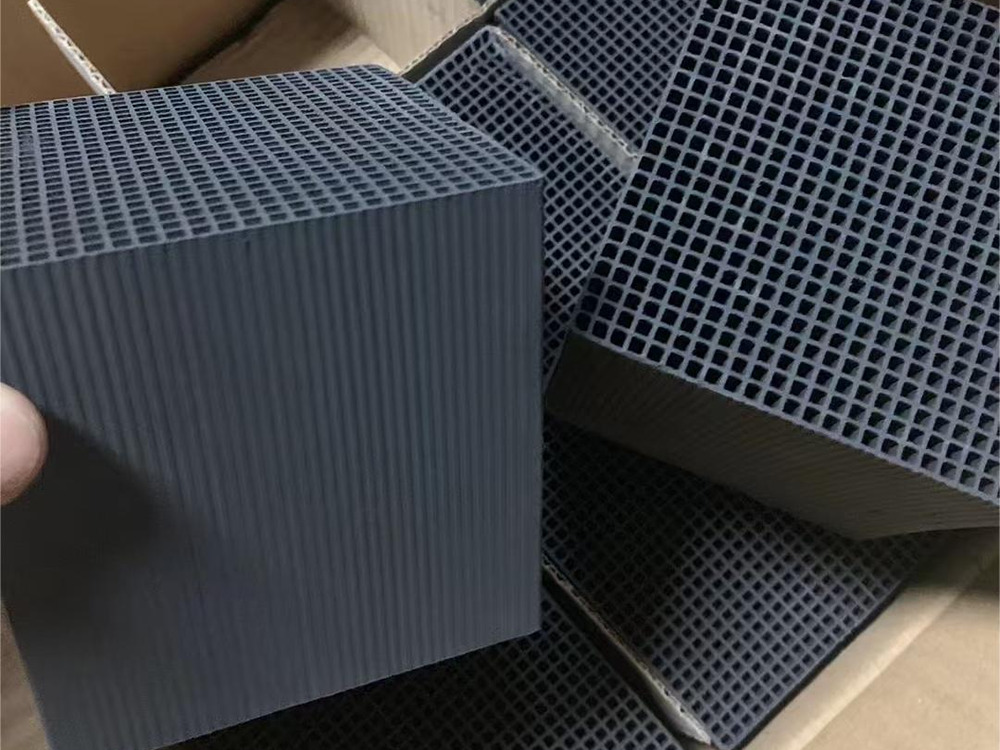

4. Adsorption method

It is the use of porous solid adsorbents to adsorb one or more pollutants on the surface of wastewater, purifying the wastewater.

5. Extraction method

This method utilizes a specific solvent to fully mix and contact with wastewater, allowing a certain pollutant dissolved in the wastewater to be redistributed and transferred into the solvent. Then, the solvent is separated from the extracted wastewater to achieve the goal of purifying the wastewater.

6. Membrane separation method, etc

Process flow of coating wastewater: coating wastewater → grid → water storage and reaction tank → reaction sedimentation tank → anaerobic biochemical tank → aerobic biochemical tank → secondary sedimentation tank → qualified discharge

5、 Characteristics of painting wastewater treatment equipment:

The wastewater generated by coating pigment production enterprises mostly contains heavy metal substances such as lead and chromium. If this type of wastewater is not properly treated, it not only wastes resources but also pollutes the environment. Therefore, for the treatment of pigment wastewater, it is not only necessary to detoxify and ensure that the water quality meets the discharge standards, but also the heavy metal resources in it can be recycled and reused.

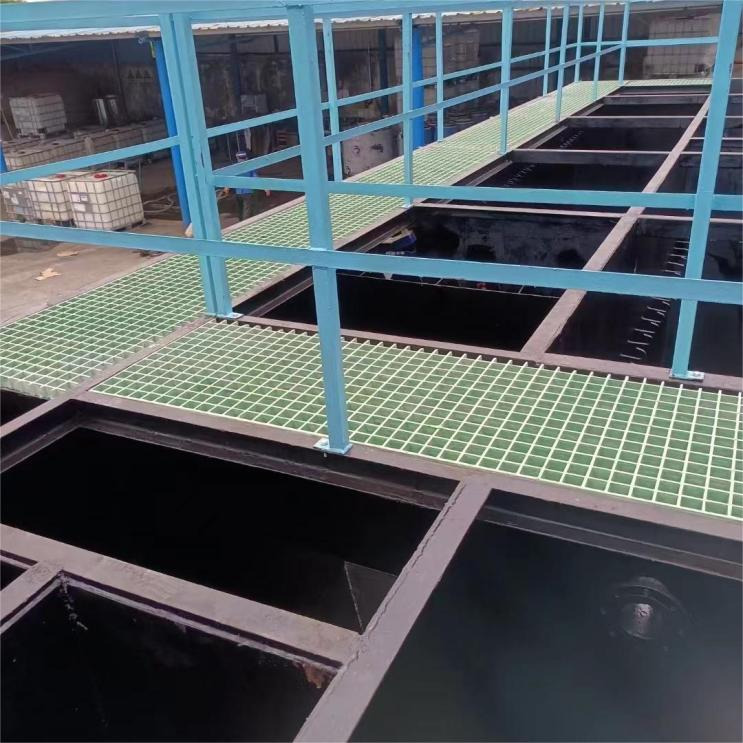

6、 Equipment picture: