Menu

Latest News

Products

1、 Product details:

Ultrafiltration, also known as ultrafiltration, is used to trap colloidal sized particles in water, while allowing water and low molecular weight solutes to pass through the membrane. The mechanism of ultrafiltration refers to the comprehensive effect of mechanical sieving on the membrane surface, membrane pore blockage, and membrane surface and pore adsorption, with sieving as the main mechanism.

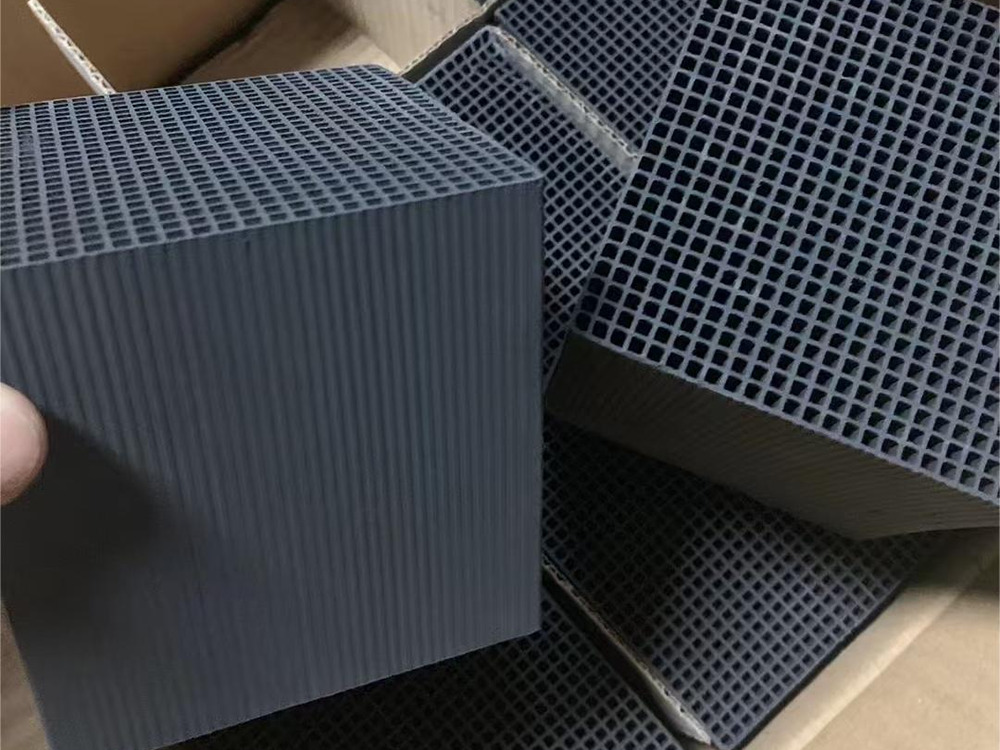

Ultrafiltration (UF) is a membrane separation technology that can purify and separate solutions. The ultrafiltration membrane system is a solution separation device that uses ultrafiltration membrane fibers as the filtration medium and the pressure difference on both sides of the membrane as the driving force. Ultrafiltration membranes only allow solvents (such as water molecules), inorganic salts, and small organic molecules in the solution to pass through, while intercepting large molecular substances such as suspended solids, colloids, proteins, and microorganisms in the solution, thereby achieving the purpose of purification or separation.

Ultrafiltration membranes are widely used in water treatment projects. Ultrafiltration technology is playing an increasingly important role in fields such as reverse osmosis pretreatment, drinking water treatment, and reclaimed water reuse. Ultrafiltration technology plays a key role in the sterilization and turbidity removal of alcoholic beverages, the removal of heat sources from drugs, and the concentration process of food and pharmaceuticals

Ultrafiltration is a membrane separation process that uses sieving as the separation principle and pressure as the driving force. The filtration accuracy is in the range of 0.005-0.01 μ m, and it can effectively remove particles, colloids, bacteria, heat sources, and high molecular weight organic substances from water. It can be widely used for the separation, concentration, and purification of substances. The ultrafiltration process has no phase transformation and operates at room temperature, making it particularly suitable for the separation of thermosensitive substances. It has good temperature resistance, acid and alkali resistance, and oxidation resistance, and can be used continuously for a long time below 60 ℃ and pH 2-11.

2、 Characteristics of ultrafiltration:

1. The ultrafiltration process has no phase change and can be separated at room temperature and low pressure, resulting in low energy consumption, about 1/2 to 1/5 of that of evaporation and freezing methods;

2. The equipment has a small volume and simple structure, resulting in low investment costs and easy implementation;

3. The ultrafiltration separation process is just a simple pressurized transportation of liquid, with a simple process flow and easy operation and management;

4. The solution does not undergo any qualitative changes during separation and concentration, making it suitable for the treatment of flavor preserving and thermosensitive solutions;

5. Suitable for the recovery of trace amounts of precious and large molecular substances from dilute solutions, as well as the recovery of low concentration large molecular substances;

6. Capable of classifying and separating substances of different molecular weights;

7. Ultrafiltration membrane is a uniform continuous body made of polymer, without any impurities during use

3、 Technical parameters:

Usage status: cross flow filtration or full flow filtration, reverse flushing and rapid flushing

Backwash pressure:<0.1MPa

Backwash flow rate: 200L/m2/hr

Backwash frequency: varies with inlet water quality for 15-60 minutes

Backwash time: 30-60 seconds

Chemical flushing: Depending on the membrane material and membrane fouling situation

Sterilization treatment: Rinse with NaClO once a week to once a month

Features: It can significantly improve the flushing intensity and facilitate membrane regeneration

5、 Scope of adaptation:

Manufacturing industry: automotive glass, steel, paper, textile, etc

Power industry: boiler, thermal power generation, cooling cycle, etc

Catering industry: beverage, food, dairy, drinking water, hotels, etc

Electroplating industry: coating, lighting, cooling, metal plating, LED lights, etc

Optoelectronic industry: photovoltaic photovoltaic lighting, new energy LED lights, etc

Electronics industry: electrical chips, circuit boards, microcontrollers, electronic components, etc

Pharmaceutical industry: Medical devices, oral liquids, finished drugs, biologics, etc

Energy industry: oxide semiconductor silicon materials, polycrystalline silicon metal extraction, etc

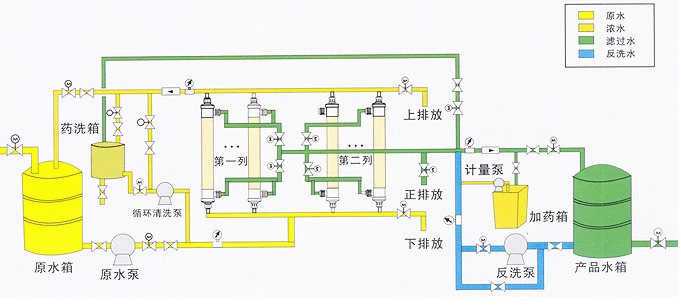

6、 Process flow:

Previous: No More

Next: No More