Menu

Latest News

1、 Product details:

The 4-72 centrifugal fan is the earliest fan used in China, but it is also the most common fan used. From high-rise buildings to underground railways, from boiler blowing to factory ventilation, the 4-72 fan can be seen everywhere. The 4-72 centrifugal fan is used for indoor ventilation and air exchange in general factories and large buildings, and can be used as both input gas and output gas. Air and other gases that are non flammable, harmless to human health, and non corrosive to steel materials. The 4-72 centrifugal fan is a common exhaust fan product. Due to its high efficiency, it is widely used in industrial and mining plants, civil buildings, large public buildings, power plants and other places. It can also be used as a supporting equipment for air treatment facilities and hot air circulation facilities. There are currently two types of centrifugal fans commonly used in the market: 4-72-A and 4-72-C.

2、 Advantages:

1. Good ventilation and air exchange effect. The 4-72 centrifugal fan has good exhaust effect and is very suitable for use in pipeline ventilation or air supply;

2. Strong applicability, the 4-72 centrifugal fan is commonly used as a fan for transporting air through pipelines, and can be used in non corrosive, flammable, and explosive gas environments.

3. Low noise, the 4-72 centrifugal fan is designed with a reasonable impeller angle based on aerodynamics. During operation, there is no mechanical friction, and the reasonable blade shape minimizes noise; The noise generated by the 4-72 centrifugal fan is high-frequency noise, which can be soundproof as long as there are obstacles.

4. Smooth operation, optimized impeller design reduces axial force to the lowest possible level, with efficient impeller and static and dynamic balance correction, ensuring smooth operation of the whole machine. Without any vibration reduction device, the bearing amplitude is relatively small.

5. Less maintenance is required due to the backward tilting impeller, which is less likely to adhere to dust and other media. The motor uses imported bearings.

6. Easy to maintain, some models can be equipped with cleaning doors, which do not require disassembly for maintenance and cleaning, saving time and effort.

7. Durable and sturdy, the casing and impeller are made of high-quality steel plates, making the fan more sturdy. The surface of the whole machine is treated with spray coating, which has strong oxidation resistance and is not easily corroded.

3、 Selection precautions:

1. Usually, the various parameters and performance curves provided by fan manufacturers are measured under standard conditions: that is, the medium is clean air at standard atmospheric pressure; The temperature is equal to 20 ℃; The air density is equal to 1.2Kg/m. If the fan is used under non-standard conditions, it should be converted to parameters under standard conditions before selection.

2. The standard product of a general 4-72 centrifugal fan does not have a heat dissipation wheel. If the fan is used to transport high-temperature gases (temperature below 200 ℃), a heat dissipation wheel should be added when selecting.

3. When the operating environment has high requirements for the vibration of the fan (such as the fan being installed on a floor slab), a shock absorber can be used in conjunction. When selecting, it should be noted that the standard configuration of the fan does not come with a shock absorber. Users can purchase shock absorbers themselves or indicate the addition of shock absorbers when ordering the fan.

4. Generally, the standard outlet angles for 4-72 centrifugal fans are 0 °, 90 °, and 180 °.

4、 4-72, A type centrifugal fan equipment picture:

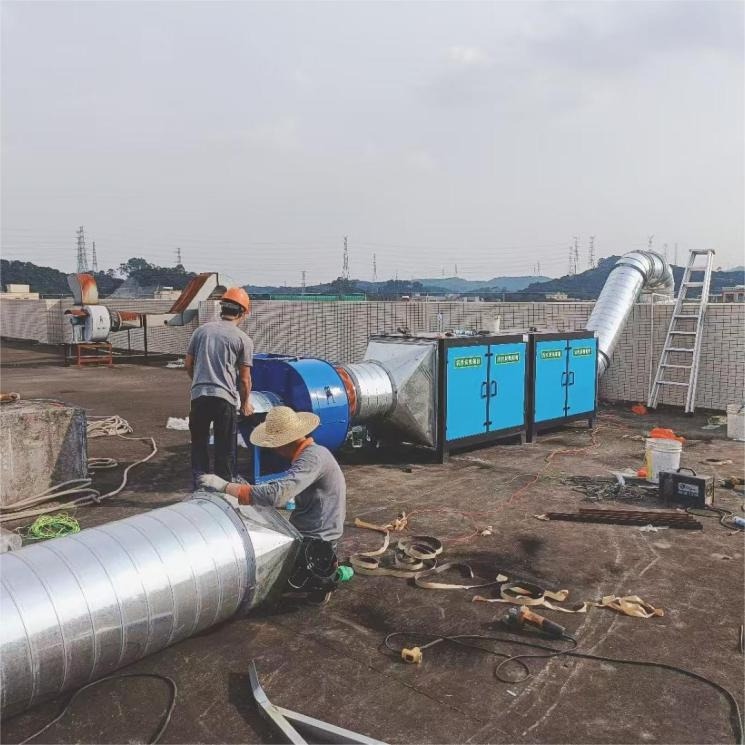

5、 4-72, A-type fan installation site:

Previous: 4-72, C type, centrifugal fan