Menu

Latest News

Products

1、 Overview:

Spray painting wastewater treatment equipment mainly utilizes raw materials such as oil substances, paints, pigments, fillers, and additives through mixing, emulsification, and other processes in paint production. The wastewater generated during the production process has complex water quality components, high pollutant concentrations, and large fluctuations in wastewater quality and quantity. In addition, cleaning paint containers and equipment also generates wastewater. Wastewater mainly contains organic substances such as resin, solvents, additives, mineral oil, vegetable oil, soap, pigments, etc., with high COD concentration. The concentration of process water pollution generated during the production process is high, with COD exceeding 30000mg/L, but the amount of water is small; The concentration of water pollution in equipment and site cleaning is low, but the cleaning time is relatively concentrated every day. This leads to significant fluctuations in wastewater quality and quantity, as well as a high concentration of suspended solids. Due to its process characteristics, paint wastewater generally contains most of the raw materials, semi-finished products, and finished products used in the production process. The water quality is complex and highly toxic. According to the owner's introduction, the wastewater mainly contains pollutants such as butanol, xylene, formaldehyde, phenols, epoxy resin, various additives, animal and vegetable oils, heavy metals, etc., which lead to high COD concentration in the wastewater. According to the requirements of the bidding document, all industrial wastewater must be zero discharged and meet the standards for reuse. The treatment process must be stable and reliable. The main pollutants in paint wastewater come from raw materials, semi-finished products, and finished products in the production process. These pollutants remain in the process water and clean water, and enter the wastewater treatment plant together, directly leading to high COD concentration and high toxicity in the wastewater. Most domestic paint wastewater is treated using a combination of physicochemical and biochemical methods, with air flotation being the common method. Due to the mature and reliable biological contact oxidation process, most processes choose contact oxidation. The wastewater treatment plant currently in operation for painting also adopts the above process.

2、 The workflow of the spray painting wastewater treatment equipment is as follows:

1. The wastewater first passes through a grid to remove particles and debris, and then flows into the regulating tank by itself.

2. Adjust the balance of water quantity and quality in the regulating pool. When the water quality and quantity change under certain conditions, these conditions will be automatically adjusted by the dosing device to ensure that the system's water quantity and quality meet the requirements of process operation.

3. Wastewater flows into the integrated air flotation equipment to remove emulsified oil and suspended solids, and then enters the coagulation reaction tank to further remove fine suspended solids, oil, organic matter, etc.

4. The effluent from the coagulation reaction tank enters the integrated inclined tube sedimentation tank to further remove floating oil, some colloids, and small particles in the water, making the effluent clear and transparent.

5. The treated water after sedimentation enters the ozone contact tank, where the sterilization effect of ozone is used to disinfect the treated water. The sterilized water then enters the clean water tank.

6. Finally, the water in the clear water tank flows into the disinfection contact tank for secondary disinfection and sterilization, and then meets the discharge standards.

3、 Process flow of spray painting wastewater equipment:

1. Collection tank: Wastewater flows into the collection tank by itself. Considering the large amount of SS and fine colloids in the wastewater, compressed air agitation is used to prevent sedimentation.

2. Regulating tank: The wastewater enters the regulating tank after being separated from oil, and the water quality and quantity are regulated by adding chemicals for flocculation and sedimentation.

3. Air flotation tank: Add flocculant PAM to coagulate the floating oil and suspended solids in the wastewater, and then enter the air flotation tank.

4. Slant tube sedimentation tank: removes fine suspended solids from wastewater to make the effluent clearer.

5. Comprehensive regulating tank: Homogenize and regulate wastewater to meet the requirements of subsequent biochemical treatment in terms of water quality and quantity.

6. Anaerobic tank: carries out organic matter hydrolysis and acidification, where a large amount of organic matter is decomposed and transformed.

7. Hypoxia pool: Perform denitrification and denitrification treatment to remove nitrate nitrogen from the reflux water.

8. Aerobic tank: using denitrifying bacteria to convert nitrate nitrogen in the reflux water into nitrogen gas, thereby removing nitrogen; The effluent from the anoxic tank entering the aerobic tank flows back to the anaerobic tank for denitrification and denitrification treatment.

9. Clear water tank: Conduct deep treatment and disinfection of water quality, remove microorganisms, organic matter, etc. from the effluent, and make the effluent meet the discharge standards.

10. Standard discharge: The treated effluent enters the clean water tank and can be discharged after passing the standard test.

4、 Precautions for using spray paint wastewater treatment equipment:

1. When using spray painted wastewater treatment equipment, operators should pay attention to the correct operation of switches or control devices. Only by opening the knife switch and feeling a clear break point can the safe operation of the equipment be ensured.

2. When operating the equipment, it is necessary to hang a sign that reads "No Switching on, Someone is Working" in a prominent place, and a dedicated person should regularly inspect the operation of the equipment and replace damaged components in a timely manner.

3. If damaged or unusable electrical appliances such as wires and sockets are found, they should be replaced with new ones in a timely manner to ensure the normal operation of the equipment.

4. When carrying out maintenance and repair work, relevant personnel should be notified first to avoid safety accidents caused by improper work.

5. Cover the entrance of the device to prevent accidents or large solid objects from falling in.

6. The pH value of the wastewater entering the equipment must be between 6-9, as being acidic or alkaline can affect the normal growth of biofilms.

7. The fan usually needs to have its oil changed once every 6 months to improve its service life.

In short, when using spray sewage treatment equipment, it is necessary to strictly follow the relevant regulations and operating procedures to ensure the normal operation of the equipment and the safety of the operators.

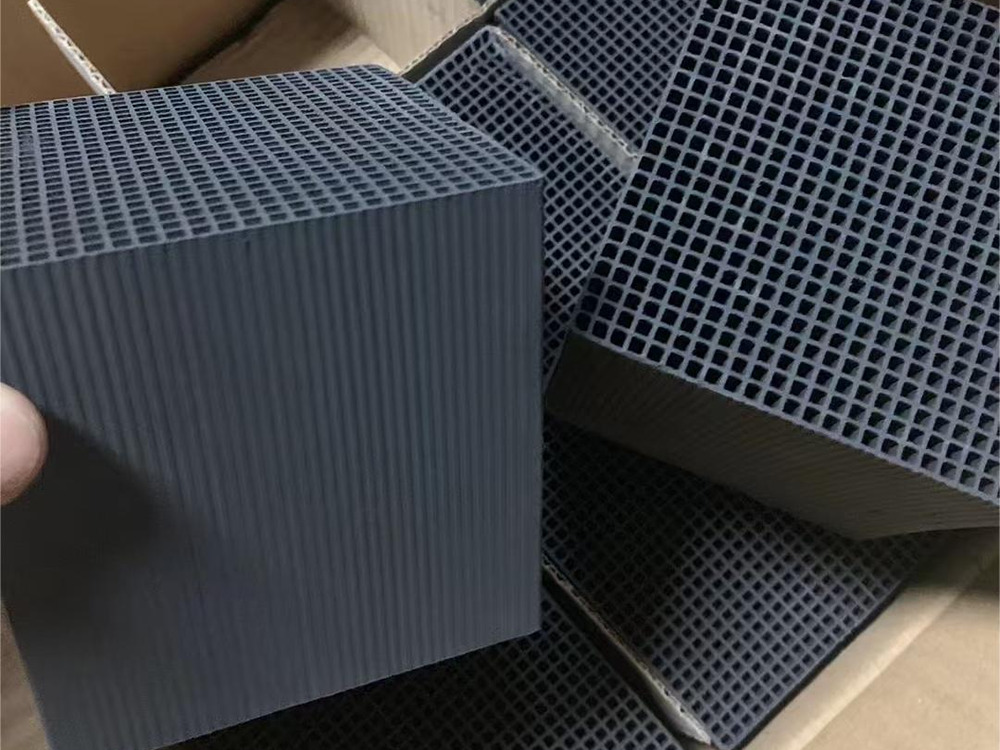

5、 Picture of spray painting wastewater treatment equipment: