Menu

Latest News

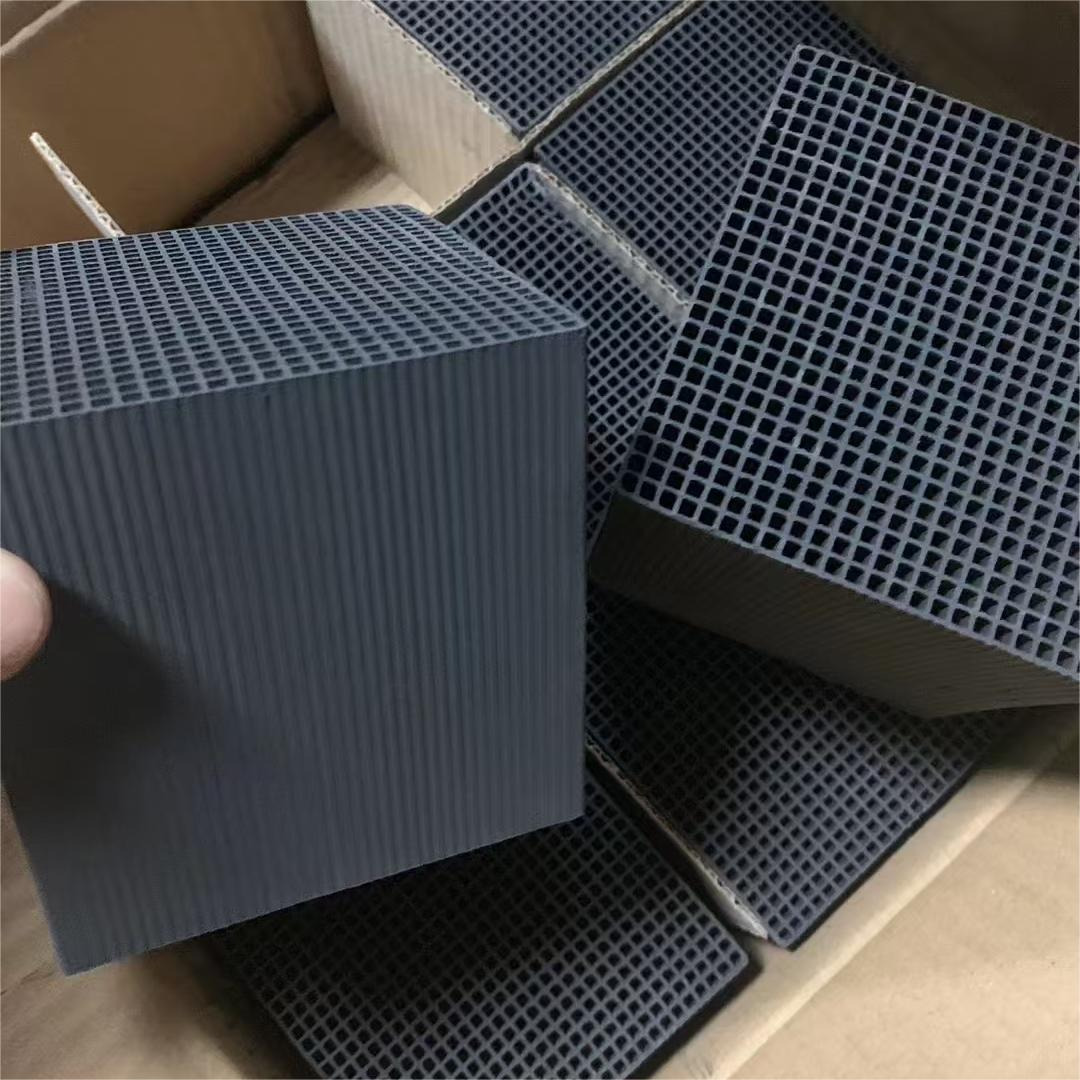

1、 Product details:

Honeycomb shaped activated carbon is a new type of environmentally friendly activated carbon waste gas purification product that can effectively reduce odors and pollutants, meeting the national first level emission standards for waste gas. The main raw materials of this product are high-grade coal activated carbon powder, high iodine value coconut shell activated carbon powder, and super decolorizing wood activated carbon powder. Most of the domestic market uses high-grade coal activated carbon powder to manufacture honeycomb shaped activated carbon, so it is called honeycomb shaped activated carbon.

2、 The preparation of activated carbon first requires carbonization of the raw materials:

Carbonization, also known as pyrolysis, is the process of heating raw materials under isolated air conditions, typically at temperatures below 600 ℃. Sometimes raw materials are first dissolved in inorganic salts before carbonization. After carbonization, activated carbon raw materials will decompose and release gases such as water vapor, carbon monoxide, carbon dioxide, and hydrogen; The raw material decomposes into fragments and reassembles into a stable structure. These fragments may be composed of some microcrystals. Microcrystals are formed by stacking two or more sheet-like structures with carbon atoms arranged in a hexagonal lattice. But there is no fixed crystal structure for stacking. The size of microcrystals is related to the composition and structure of the raw materials, and is influenced by the carbonization temperature, generally increasing with the increase of carbonization temperature. After carbonization, there are still some residual hydrocarbons attached to the boundary atoms of the microcrystals.

3、 Activation of semi-finished activated carbon products:

Activation is the process of heating carbonized materials in the presence of oxidants to produce activated carbon products. When the temperature of the oxidation process is between 800-900 ℃, steam or carbon dioxide is generally used as the oxidant; When the oxidation temperature is below 600 ℃, air is generally used as the oxidant. There is only a rough understanding of the role played by the activation process. During the activation process, the adsorbed hydrocarbons during carbonization are burned off, and the carbon and hydrogen atoms on the edges of the original pores are burned off, which expands the pores and burns through the pores. Activation transforms activated carbon into a good porous structure, resulting in carbonized and activated crystal flakes.

Activated carbon can only be produced by specialized enterprises, and the production equipment is not generally large, especially for the treatment of decoration pollution. The production process of activated carbon is even more complex, and not all activated carbon can treat decoration pollution. Some are used for water purification, while others are used for air purification. They are divided into materials such as coal, wood, fruit shells, etc.

4、 Technical parameters:

|

项 目 Subject |

指 标 Index |

|

|

规 格 Specification (mm) |

50*100*100 |

100*100*100 |

|

碘吸附值 Iodine Absorb (mg/g) |

≥550 |

|

|

比表面积 Specific Surface Area (㎡/g) |

≥600 |

|

|

四氯化碳 CTC (%) |

≥65 |

|

|

抗压强度 Compressive strength(mpa) |

0.9 |

|

|

水 份 Moisture (%) |

≤5 |

|

|

方 孔 Square hole (in)2 |

150 |

|

|

壁 厚 Wall thickness (mm) |

1.0 |

|

|

使用温度 Temperature (℃) |

≤400 |

|

|

体积密度 Bulk Density g/cm3 |

0.35-0.60 |

|

|

苯吸附率 Adsorption rate of benzene % |

动态吸附≥37 |

|

|

苯吸附率 Adsorption rate of benzene % |

静态吸附≥52 |

|

|

空塔风速 |

0.8米/秒 |

|

|

孔密度 |

100孔/平方英寸、150孔/平方英寸 |

|

6、 Purpose:

Suitable for the treatment of organic waste gas (triphenyl and toxic and harmful gases) from high air volume, low concentration factories. Suitable for indoor air purification and treatment of cooking fumes and exhaust gases. Air conditioners, refrigerators, copiers, etc. are used to remove odors. And it can be used as a catalyst carrier.

Used for gas-phase adsorption of activated carbon, adsorption and recovery of organic solvents such as benzene, toluene, xylene, acetone, oil and gas, CS2, etc

Cigarette filters, decoration deodorization, indoor air purification (removal of harmful gases such as formaldehyde and benzene), purification of industrial gases (such as CO2, N2, etc.)

Petrochemical industry production, natural gas purification, desulfurization, deodorization, and wastewater treatment

Air purification and deodorization in biochemical, paint industry, underground places, leather factories, and animal husbandry facilities

Adsorption of odor from flue gas, adsorption of sulfides, removal of mercury vapor, and reduction of dioxin production

7、 Product image:

8、 Installation site:

Previous: Coal based columnar activated carbon

Next: No More